By ON Semiconductor / Fairchild 165

MB10S is a rectifier bridge diode widely used in power systems. This is a rectifier bridge with four rectifier diodes, generally used to convert AC to DC. Each rectifier diode conducts electricity, allowing current to flow in a certain direction and blocking it in the opposite direction.

The MB family of bridge rectifiers is a 0.5 A rectifier family that achieves high surge current absorption within a very small foot print. Devices in the family are also rated to breakdown voltages of up to 1000V. These features make the MB family ideal for small power supplies that need a little extra surge capability.

Ⅰ.Specification parameters of MB10S

•Capacitance:470pF

•Product Type:Bridge Rectifiers

•Termination type:Solder Pad

•Installation style:SMD/SMT

•Package/Case:SOIC-4

•If-forward current:500 mA

•Vf-forward voltage:1 V

•Peak reverse voltage:1 kV

•Maximum surge current:35 A

•Length:4.95 mm

•Height:2.7 mm

•Width:4.2 mm

•Minimum operating temperature:-55℃

•Maximum operating temperature:+150℃

•Pd-power dissipation:1.4 W

•Ir-reverse current:5 uA

•Vr-reverse voltage:1 kV

•Shell code (imperial):1206

•Forward voltage:800 mA

•Current-average rectification (Io):500 mA

•Maximum forward surge current (Ifsm):35A

•Peak non-repetitive surge current:35A

•Voltage at different If-Forward (Vf):1V @ 500 mA

•Current-reverse leakage at different Vr:5µA @ 1000V

Ⅱ.Functions and functions of MB10S

1.Rectifier:MB10S is a rectifier bridge, which is an electronic component that converts alternating current into direct current. In the rectifier circuit, MB10S uses four internal rectifier diodes to achieve AC to DC conversion. These diodes have a unidirectional conductivity that allows current to pass in one direction and blocks the flow of current in the reverse direction. When alternating current passes through MB10S, the internal rectifier diode will turn on and off respectively according to the positive and negative half-waves of the voltage, thereby converting the alternating current into direct current. This rectification process eliminates the negative half-wave of the alternating current and retains only the positive half-wave, so the output direct current has a stable and smooth waveform. The four rectifier diodes of MB10S are connected in a bridge form. This structure can effectively reduce the resistance and voltage drop in the circuit, thereby improving the rectification efficiency. At the same time, MB10S also has the advantages of compact packaging, easy installation, and stable operation, so it is widely used in many electronic equipment and power supplies.

2.Power supply control:MB10S plays the role of rectification and current control in the power circuit. It is a rectifier bridge that converts AC power into DC power while also controlling the direction of current flow. Through the rectification function of MB10S, AC power can be converted into DC power to provide stable power supply for electronic devices. At the same time, MB10S can also control the flow direction of current to ensure that current flows in the correct direction, thereby avoiding problems such as short circuit or reverse current in the circuit.

3.Power supply application:MB10S is a very common power regulator and is often used in various power circuits, such as adapters, power supplies and power management circuits. In these applications, its main role is to ensure that the device can obtain stable DC power from the AC power supply. MB10S is a switching power supply regulator with high efficiency and low power consumption. It has a wide input voltage range and can accommodate a variety of different power inputs. At the same time, it also has functions such as output overvoltage protection and overheating protection, which can effectively protect the safety of circuits and equipment.

4.Current control direction:MB10S is a half-bridge driver that controls the direction and flow of current by driving two high-side and two low-side switches. Its four rectifier diodes play a very important role in this process. During the operation of MB10S, the four rectifier diodes are turned on and off in turn to control the flow of current. Specifically, when a high-side switch is turned on, the corresponding rectifier diode is turned off, and the current flows to the load through the other high-side switch and the corresponding rectifier diode. Similarly, when a low-side switch is turned on, the corresponding rectifier diode is turned off, and current flows to the load through the other low-side switch and the corresponding rectifier diode. In this way, the MB10S ensures that current flows in the correct direction in the circuit. At the same time, it can also effectively prevent dangerous situations such as short circuit and overcurrent, and protect the safety of circuits and equipment.

5.Rectifier bridge stack:The rectifier bridge stack is an electronic component used to convert alternating current into direct current. MB10S is a common rectifier bridge stack model, which is composed of four rectifier diodes. This rectifier bridge stack is widely used in power supplies and electronic equipment and is one of the key components to achieve power conversion and circuit protection. Alternating current is a common form of energy in power supplies and electronic equipment. However, most electronic devices require DC power to operate, so AC power needs to be converted into DC power. The function of the rectifier bridge stack is to achieve this conversion. It consists of four rectifier diodes, usually packaged together for ease of use. The rectifier diode is the core component of the rectifier bridge stack. It has unidirectional conductivity and can only allow current to flow from the positive pole to the negative pole, thereby realizing the conversion of alternating current to direct current. In a rectifier bridge stack such as MB10S, four rectifier diodes are usually connected in a certain way to achieve better rectification effect and higher reliability.

Ⅲ.Principle and structure of MB10S

•Principle

The rectifier bridge MB10S is a bridge rectifier circuit composed of four diodes. Its principle is to use the one-way conduction characteristics of the diodes to convert alternating current into direct current. When the input alternating current is a positive half cycle, the two diagonal diodes are turned on and the current is directed to the negative pole. When the input alternating current is a negative half cycle, the other two diagonal diodes are turned on and the current is directed to the positive pole. By alternating conduction, the rectifier bridge MB10S can convert alternating current into direct current.

The rectifier diode is a semiconductor device whose basic principle is that when a forward voltage is applied, current can flow through it, forming a conductive state; while under reverse voltage, current cannot flow, forming a cut-off state. The main function of the rectifier diode is to conduct the current in one direction and cut off the current in the reverse direction, thereby achieving the rectification function.

When the input is AC power, the rectifier bridge stack in MB10S will convert the AC signal into a DC signal with direction. During the positive half cycle, two of the diodes conduct, allowing current to pass; during the negative half cycle, the other two diodes conduct, allowing current to pass. In this way, the rectifier bridge stack can achieve current flow in the same direction regardless of the polarity of the input signal.

MB10S is composed of four rectifier diodes, forming a rectifier bridge stack. The basic structure of the rectifier bridge stack is four diodes arranged in a bridge shape, usually called a "bridge arm". The arrangement of these four diodes is such that under AC input, no matter it is a positive half cycle or a negative half cycle, at least two diodes are in the conducting state, thereby achieving rectification.

•Structure

Pin configuration:The number of pins of MB10S is four, and each rectifier diode occupies one pin. The pin configuration may vary depending on the package type, but typically includes an anode (+), a cathode (-), and two pins for connecting the rectifier diodes.

Package:MB10S usually adopts inline package, in which the rectifier diode is packaged in a small housing for easy installation and connection.

Rectifier diodes: MB10S contains four rectifier diodes, each diode has two pins, namely the positive pole (anode) and the negative pole (cathode). These four rectifier diodes form a rectifier bridge stack through a specific arrangement.

Arrangement:These four rectifier diodes are arranged in a bridge-shaped structure, usually called a rectifier bridge. The arrangement of the rectifier bridge ensures that at least two rectifier diodes are conducting during the positive and negative half cycles of the input AC signal.

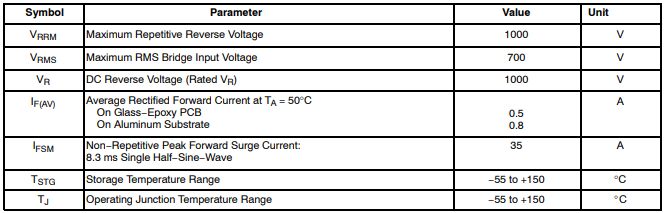

Ⅳ.Absolute Maximum Ratings of MB10S

(Values are at TA=25°C unless otherwise noted)

Ⅴ.Electrical Characteristics of MB10S

(Values are at TA=25°C unless otherwise noted)

Ⅵ.Power supply circuit suitable for MB10S

1.Adapters and chargers: MB10S rectifier bridge stack can be used in the rectification part of AC adapters and chargers. In the AC adapter, the function of the rectifier bridge stack is to convert alternating current into direct current to provide stable power for subsequent circuits. In the charger, the rectifier bridge stack is also an essential component, which can ensure the stability of the output DC voltage, thereby providing reliable charging power for batteries or electronic devices.

2.Power tools and equipment: MB10S is a diode that can be used in rectifier circuits to convert AC power to DC power. This type of diode is very common in power tools and equipment because it helps these devices convert AC power to DC power to meet their operating requirements. For example, many power tools require DC power to operate properly, and the MB10S can rectify AC power into DC power to provide the tool with the power it needs.

3.Power management circuit: MB10S can be used for rectification and current control in the power management circuit to ensure the stability and reliability of the power supply. MB10S is a diode that converts AC power to DC power. In power management circuits, this rectification is very important because it converts alternating current into the direct current required by the device, thereby ensuring the normal operation of the device. MB10S can also be used to control the size of the current to protect the circuit from damage by excessive current. It can be used with other electronic components, such as transistors or integrated circuits, to achieve precise control of electrical current. By controlling the size of the current, the stability and reliability of the power supply can be ensured, thereby extending the service life of the equipment.

4.LED driving power supply: MB10S plays a key rectifying role in LED lighting applications, especially in power circuits that need to convert AC power to DC power to drive LEDs. The four rectifier diodes of MB10S form a rectifier bridge stack, which is used to rectify AC power into DC power. The function of the rectifier bridge stack is to ensure that the current flows in one direction to produce a stable DC output. The use of MB10S helps smooth the output voltage of the LED driver power supply, reduce pulsation in the power supply, and provide a more stable power supply. This helps prevent the LED from flickering or not functioning properly due to unstable power supply.

Ⅶ.Methods to prevent overcurrent in MB10S

1.Use current protection devices: You can use fuses, thermistors, current limiters and other devices specially designed for current protection. These devices can cut off the circuit when the current reaches a set value, preventing damage caused by overcurrent.

2.Add a current limiting resistor (current limiting resistor): Add an appropriate current limiting resistor to the input circuit of MB10S to limit the flow of current. This ensures that the current is within a safe range and prevents overcurrent from damaging circuit components.

3.Use current protection ICs: Some specialized current protection integrated circuits (ICs) can be integrated into the circuit to provide more precise current protection and monitoring functions.

4.Design a current feedback loop: Add a current feedback loop to the circuit to monitor changes in current and control the power output. This feedback mechanism can be used to dynamically adjust the current to ensure operation within a safe range.

5.Overcurrent protection circuit design: A special overcurrent protection circuit can be designed to detect the current through a sensor and cut off the circuit when it exceeds the set value. This method can respond quickly when the current exceeds the threshold, providing more effective overcurrent protection.

Frequently Asked Questions

1.What special precautions should be taken when installing MB10S?

MB10S has pins in both positive and negative directions to ensure correct connection and avoid reverse connection. Wrong polarity connections may result in circuit inoperability or component damage. MB10S may be available in different types of packages, ensure that the chosen package is suitable for the specific application scenario and can be effectively mounted on the target circuit board.

2.What means MB10F?

MB10F Bridge Rectifier MB10f is a surface Mount Glass passivated bridge rectifier with a Maximum Peak reverse voltage of 1000 volts and an average output current of 0.8 Ampere.

3.Does the MB10S require a heat sink, especially in high power applications?

If the MB10S is operated in a high power application, it may generate more power dissipation. In this case, the heat sink can help conduct the generated heat efficiently into the surrounding environment to prevent the MB10S from overheating.

4.What is the conduction voltage drop of MB10S?

MB10S is a rectifier bridge stack composed of four rectifier diodes. For rectifier diodes, the forward voltage drop when conducting is a critical parameter. Typically, the conduction voltage drop of a rectifier diode is between 0.7V and 1.2V, this value may vary slightly.

5.How does MB10S maintain the stability of the power circuit?

Consider adding overcurrent and overvoltage protection circuits to the circuit to prevent damage to the circuit from overcurrent and overvoltage. These protection circuits ensure that circuits are disconnected in time under abnormal conditions, protecting power circuits and connected equipment.